This Porsche 911 (930 Turbo) is a well-known Porsche Club car, regularly attending national shows, club events and driving tours. The owner has a very keen eye for detail and despite the car being 40+ years old, it is kept in exemplary condition, especially for a car so extensively used and enjoyed, just as a Porsche should be.

The 930 Turbo arrived at the AMS workshop for a comprehensive engine rebuild to include a turbocharger recondition. Fundamentally the engine was in operational condition upon arrival, however the cylinder leakages were high, there were a few oil leaks, it was a bit smoky and lacked the true punch and performance of a Porsche 930 Turbo on song!

How we went about the Porsche 930 Turbo Engine Rebuild...

Step 1 – 930 Turbo Engine Inspection

As with all air cooled Porsche 911 engine rebuilds, the team at AMS performed a full inspection prior to engine removal and dismantling. After an extensive discussion, it was agreed with the client in advance to perform a full ‘bottom end’ comprehensive engine rebuild on this Porsche 930 Turbo. This decision was taken partly to explore the full internal condition of what was certainly a very original engine, and also to replace all of the wear items throughout the entire engine.

Step 2 – Engine Cleaning & Reconditioning

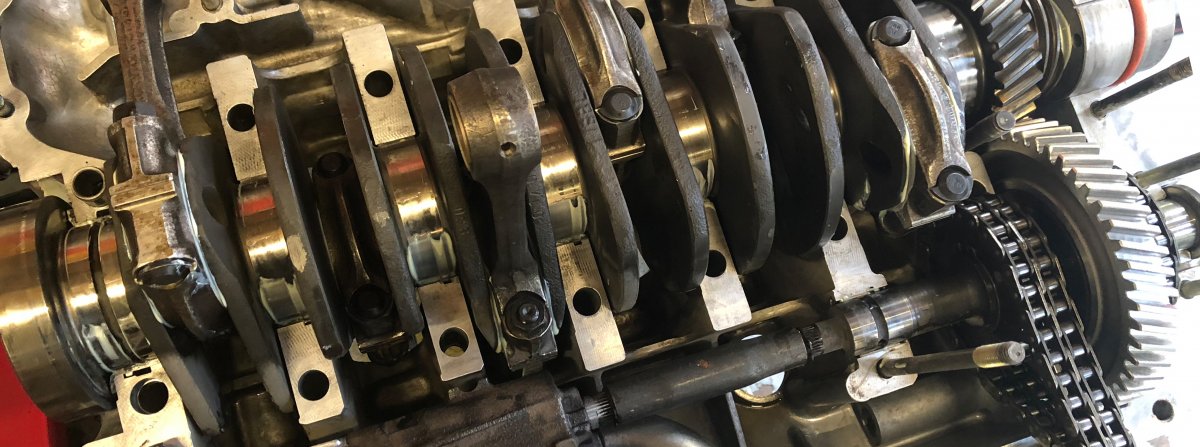

It was found upon inspection of the dismantled engine that the overall condition of this Porsche 930 Turbo engine was good. The crankshaft, camshafts, pistons and liners were all serviceable after routine cleaning and measuring. The big end bearings, main bearings, timing chains and guide ramps were all routinely replaced. The oil pump overhauled, pistons thoroughly decontaminated and reinstalled with new OEM piston rings. The cylinder heads were fully reconditioned to include new exhaust and inlet valve guides, new valve springs and stem seals.

Engine cleaning and reconditioning benefits

Once reassembled, the engine compressions were returned to ‘as new’ condition, helping the engine to run smoothly, efficiently and of course with factory level performance. With all the ‘moving part’ wear items replaced the oil pressure was restored and the engine will be healthy and reliable for years to come.

Step 3 – Parts Replacement & Engine Rebuild

In addition, the broken / rotten exhaust manifold studs were surgically removed and replaced for new. Rotten oil lines were replaced and the reconditioned turbocharger installed. The customer supplied a replacement exhaust system which we installed at this stage. The inlet manifold, tinwork, fan housing and all pipework was meticulously cleaned and reinstalled, along with new HT leads, spark plugs, belts and other consumables.

Save money while the engine is in pieces

Effectively our client took advantage of his engine being apart to perform a planned exhaust upgrade free of additional labour expenses, as well as simultaneously future proofing his turbocharger. With all the ignition and engine consumables replaced this engine will only require basic routine maintenance for the foreseeable future.

Step 4 – 930 Turbo Engine Refit, Inspection & Test Drive

The fully rebuilt Porsche powerplant was now ready to be refitted to the freshly cleaned engine bay, and once fresh oil was added the flat 6 fired up for the first time. The engine was subject to a thorough inspection, road testing and setup of the ignition timing etc before the vehicle was ready to collected by the very happy customer to enjoy the summer with his Porsche 930 Turbo, attending all the shows in the diary.

If AMS Porsche can assist you with a full or partial engine rebuild for your air cooled Porsche please do get in contact, we would love to hear about your car and help if possible!